Rolex Bracelet Repinning & Repair

Specialist restoration for Rolex Jubilee and Oyster bracelets. We eliminate “stretch” and replace worn pins to restore the factory-tight feel of your timepiece.

Expert Rolex Bracelet Repair in Lancashire & UK-Wide

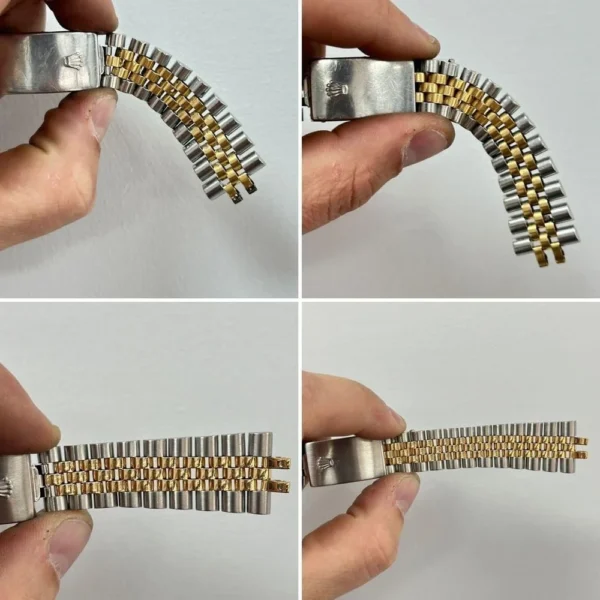

The “Rolex Stretch” is a phenomenon known to almost every collector. Over years of daily wear, dirt and grit act like a grinding paste between the links and pins of your Jubilee or Oyster bracelet. This friction slowly wears away the metal, causing the bracelet to loosen, droop, and lose its structure. Eventually, this wear becomes critical, and a pin can snap—risking your valuable timepiece falling from your wrist.

At Prime Time Watch Repairs, we specialise exclusively in the restoration of Rolex bracelets. Many owners believe that once a Jubilee or Oyster bracelet is stretched, the only option is a replacement from Rolex costing thousands of pounds. This is not the case. We can disassemble the complex “permanent” links, replace the worn internal pins with stronger modern steel, and rebuild the bracelet to a safe, tight condition. This preserves your original clasp code and date stamp—vital for maintaining the vintage value of your watch.

Our Rolex Repinning Process

Restoring a Rolex bracelet is precision engineering. We use a combination of traditional tools and modern laser technology to save bracelets that others would write off.

We measure the lateral play (“stretch”) of the bracelet to determine the extent of the wear. We check the clasp integrity and safety catches (Fliplock) to ensure the entire system is secure.

Unlike a simple resize, repinning requires taking the “permanent” fixed links apart. We carefully separate the links. For riveted or pressed Oyster bracelets, this involves carefully pulling the friction-fit pins without distorting the outer gold or steel caps.

Before rebuilding, we must remove the “grinding paste” (a mix of dead skin, oil, and metal dust) that caused the wear in the first place. The disassembled links go through an intensive ultrasonic bath to ensure the new pins will sit in a clinically clean environment.

We replace the worn-down, “waisted” pins with brand-new, oversized pins made from high-grade 316L stainless steel. These are often fractionally thicker than the originals to compensate for the wear in the link holes, tightening up the bracelet instantly.

If the holes in the links themselves have become oval shapes, a new pin isn’t enough. We use precision laser welding to add metal back into the worn holes, then re-drill them to the exact original diameter. This is the gold standard for restoration.

The bracelet is rebuilt link by link. Finally, we refinish the bracelet, restoring the correct brushed finish on Oyster links or the polished centre links on Jubilee models to ensure the repair is invisible.

See why hundreds of customers trust us with their watch bracelet repinning

Brands we cover for bracelet repinning

We regularly perform bracelet repinning on major brands including Rolex, Omega, TAG Heuer, Breitling, Cartier and more.

Frequently asked questions

Here are the answers to the most common questions our customers ask about bracelet repinning.

“Stretch” is a misnomer; the metal doesn’t actually stretch. Instead, the pins inside the links wear down and become thinner, and the holes in the links wear into ovals. The combined gap across all links creates the “floppy” or “droopy” effect you see when holding the watch sideways.

Yes, this is our most common request. Vintage Jubilee bracelets are notorious for stretching. We can completely dismantle the bracelet, replace the internal pins, and tighten the links, making it feel almost new again for a fraction of the cost of a replacement bracelet from Rolex.

Yes. If your clasp pops open or won’t click shut, it usually means the spring is broken or the locking blade is worn. We can replace the internal springs, re-shape the blades, or laser weld worn catch points to restore a secure “click.”

A new steel bracelet from a brand like Omega or Rolex can cost upwards of £1,000 to £2,500. Our repinning service is a fraction of this cost. Furthermore, keeping the original bracelet maintains the “codes” and period-correct look of your watch, which is vital for vintage value.

Yes. We take extra care with gold-capped or solid gold center links. We use specific tooling to ensure the soft gold is not marked or dented during the heavy-force process of removing the friction pins.

Because this is intricate, manual work involving hundreds of parts, it typically takes 2 to 4 weeks. Laser welding work may take slightly longer, but the result is a bracelet that is safe to wear for another 20 years.